Fabric expansion joints or commonly known as non-metallic expansion joints consist of multiple or single layers of elastomers and fabrics. These joints can be customized into different sizes and shapes according to operating requirements. Fabric expansion joints find their use in case of gaseous fluids. Fabric expansion joints can make ductworks flexible, which in turn can allow them to cope with several issues.

For example, due to enhanced flexibility, it allows ducts to adjust to temperature variations at the time of contraction and expansion. Besides, fabric expansion joints can alter itself at the time of movements of elements, vibrations, installation or removal of huge components, misalignments, and erection tolerances. You can find out a fabric expansion joint suitable for varying applications. An expert will help you to choose the right product.

What material is used for expansion joints?

The types of materials used in the case of expansion joints are asphalt, fiber, ceramar, sponge rubber, and cork. Known for its durability and flexibility, asphalt is blended with minerals and vegetable material. Asphalt works as a waterproof sealing. Fiber is known as a flexible, versatile, resilient and non extruding material.

Due to its flexibility, fiber is considered to be the best expansion joint material. Ceramar is resilient, flexible and light weight- it is made from isomeric polymers. Similarly, cork is renowned for its excellent expansion properties. Cork has the capacity to expand more than 140% of the previous thickness. Sponge rubber can be compressed easily. So, sponge rubber can recover up to 95% of the previous thickness- this feature makes it the best expansion joint material.

What are the types of fabrics expansion joints?

- Single layer

It consists of a single reinforced elastomeric layer

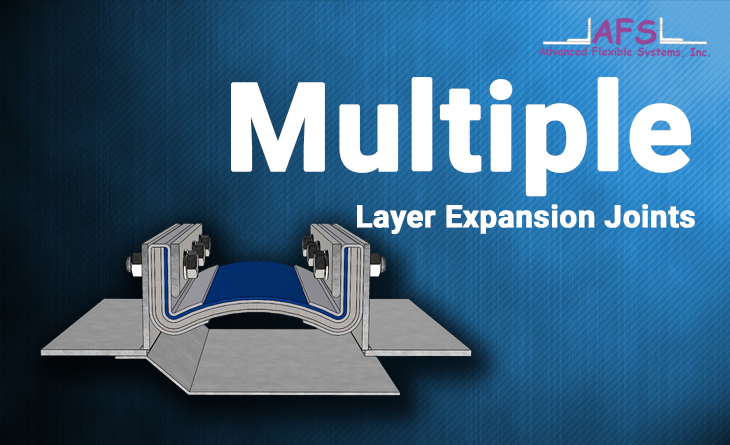

- Multiple layer

It consists of multiple layers. It’s supporting layer offer different shapes to specific configurations. This layer helps to shield the joint and hold the insulation at the right place. The insulating layer works as a thermal barrier. Chemical barrier works as a gas seal. The outer cover offers protection against external surrounding and serves as a complementary gas seal.

- Belt type or flanged type expansion joints

The flexible element of an expansion joints is similar to a flat belt. It is extremely helpful in case of installation and manufacture. Here, the materials won’t have to undergo too much stress until they need to be operated. It helps distinct kinds of frames to adjust according to the operating conditions. It eases out the task of replacing the flexible element. These expansion joints are known for their extended lifespan.

- Flanged type expansion joints or U-TYPE expansion joints

The expansion joints are known for their flexibility as they include integrated flanges at various right angles. They work as the simplest mode of connectivity. These joints are highly recommended in case of low temperature applications.

Uses of the fabric expansion joints?

Fabric expansion joints have multiple applications. Some of the fabric expansion joints can be used along with bulk media and gaseous media for industrial purposes such as:

-

- DeSOx or flue-gas desulphurization systems

- Lime and cement industry

- Drying and painting systems

- Fire protection systems

- Filter and de-dusting installations

- Ventilation systems

- Metallurgical plants

- Waste incineration plants

- Refineries

- Chemical plants

Top fabric expansion joints manufacturer and supplier in United States

Fabric expansion joints are available in several designs. You can find out the best one that can withstand torsion along with vibration. It’s important to find out the right fabric expansion joints manufacturer or supplier in US as the task of designing or manufacturing the fabric expansion joint is complicated. The supplier or manufacturer should be informed about its application, the dimensions or size of the pipings and equipments along with the environment in which they can operate.

Some fabric joints are produced with the help of a single fabric layer, whereas, other fabric expansion joints consists of numerous layers. These layers are sewed and glued together- it helps them to meet the application requirements. Fabric expansion joints can compensate to a large extent without any angular or lateral movements within several piping systems due to their high flexibility.

Get a free consultation today as these experts have relevant experience and knowledge of comprehensive test procedures. You can choose the most durable fabric expansion joints that are manufactured from high-grade materials. The appropriate manufacturing and systematic processing stages makes them the best choice.

When it comes to determining the quality or operational effectiveness of fabric expansion joints, the installation procedure plays a pivotal role. Correct installation is necessary in this case. Reach out to an expert to learn more about these joints and choose the best product. You can obtain a free price quote or get a chance to collaborate with assembly engineers according to your request.